KD Finechem: Leading DLC(Direct Liquid Cooling)

Highly Efficient & Corrosion-Resistant DLC Coolant for Data Centers

Applying 'Nano Heat Transfer Medium Manufacturing Technology'

Established in 1973, KD Finechem is a fine chemical manufacturer company dedicated to contributing to society through the highest quality and technology. The company focuses on developing eco-friendly and sustainable products that align with these principles.

KD Finechem specializes in manufacturing chemical products for not only automotive but also industrial machinery applications. In response to the growing emphasis on environmental sustainability, the company is developing environmentally friendly coolants. This includes:

Long-life antifreeze technology that extends coolant lifespan for internal combustion engines, reducing waste and resource consumption.

Fuel cell system coolant technology, designed for hydrogen fuel cell vehicles, which are considered the ultimate eco-friendly automotive solution.

Battery system low-conductivity, corrosion-resistant coolant, crucial for thermal management and the safety of electric vehicles.

Through ongoing research and development, KD Finechem is actively taking part in the expansion of eco-friendly vehicles.

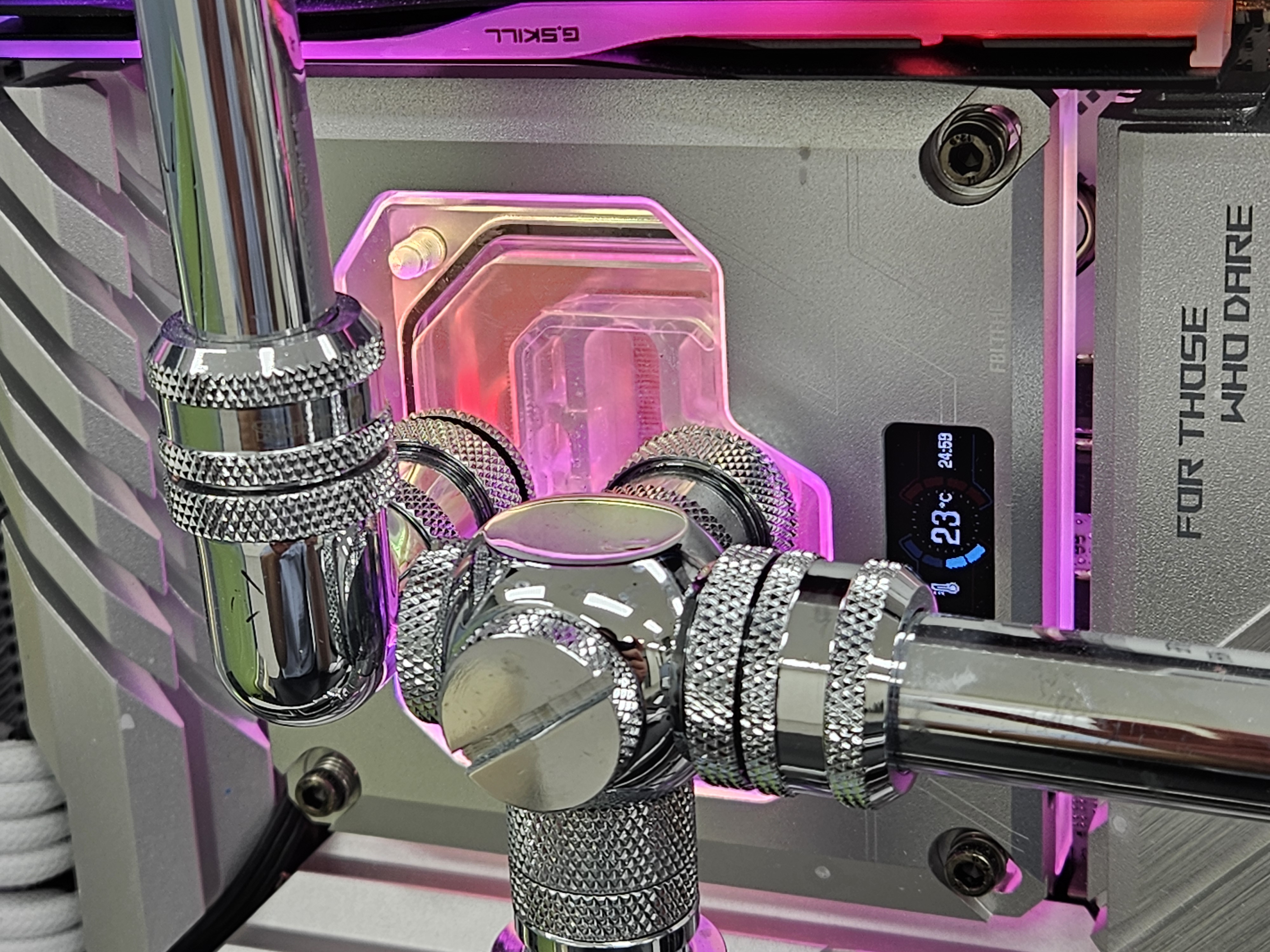

In response to the rapid growth of AI, HPC (High-Performance Computing), and eco-friendly data centers (DC), KD Finechem has developed a highly efficient coolant optimized for DLC (Direct Liquid Cooling) systems. DLC offers a superior energy-saving benefits over air cooling and has become a quintessential solution for a high-density AI servers and next-generation data centers.

Establishing as the industry standard for DLC in the DC market, KD Finechem is strengthening strategic partnerships with global IT leaders.

Advantages of Data Center Liquid Cooling

1. Enhanced Reliability & Performance

Efficient heat management ensures continuous and stable system operation.

2. Improved Energy Efficiency

Liquid offers a superior heat transfer capability compared to air, enabling more efficient cooling with reduced power consumption.

3. Reduced Operational Costs

Minimizes or eliminates air-based cooling infrastructure (e.g., chillers, CRAC [Computer Room Air Conditioning], CRAH [Computer Room Air Handler], and water pumps), reducing costs and energy consumption.

4. Optimized Space Utilization

Increased cooling efficiency allows for higher rack density, maximizing data center space.

Efficiency, Stability, and Economic Benefits

KD Finechem’s DLC enhances cooling system performance and efficiency. The KD DLC optimizes the glycol-to-water ratio based on cooling conditions to achieve maximum heat transfer efficiency. More importantly, the company developed the 'Nano Heat Transfer Medium Manufacturing Technology,' which significantly boosts the thermal conductivity.

This technology enhances water’s inherently high thermal conductivity-already 50 to 100 times greater that of air-by 3 to 5 times by utilizing the nano-sized high-conductivity particles. Moreover, it maintains a low-viscosity property, ensuring smooth coolant flow and stability under extreme temperature conditions.

KD DLC incorporates advanced corrosion protection technology using OAT (Organic Acid Technology) and hybrid additive technology to provide optimal corrosion resistance.

It offers long-term corrosion protection for various metals commonly found in cooling systems, including aluminum, aluminum alloys, copper, stainless steel, cast iron, carbon steel, and galvanized steel pipes. This prevents corrosion in pipes and heat exchangers, ensuring high thermal efficiency even after prolonged use. It also minimizes the sediment and sludge buildup, thereby reducing maintenance requirements.

KD Finechem’s DLC is environmentally friendly due to its long-lasting lifespan, waste reduction, resource conservation, and lower hazardous chemical emissions. It uses bio-degradable, low-toxicity propylene glycol (PG), with the option to supply plant-based PG upon customer request, reducing carbon emissions compared to petroleum-based PG.

KD Finechem offers customized coolant formulations to suit various DC environments and operational conditions. Even after delivery, the company provides continuous monitoring solutions, analyzing glycol-water concentration, corrosion resistance, and contamination levels to ensure proper system management.

The KD DLC is designed for long-term cost efficiency, offering an extended lifespan and minimal maintenance requirements. Through proactive monitoring and management expertise, KD Finechem optimizes maintenance efficiency, ensuring reduced cost for the customers.

KD DLC complies with major environmental and industrial regulations worldwide, including but not limited to:

‘ South Korea: K-REACH, Chemical Control Act

’ Europe: EU REACH, EU CLP regulations

‘ United States: TSCA regulations, various state-level environmental laws

’ Industry Standards: ASTM, ASHRAE, ANSI, ISO

By meeting global compliance requirements, KD Finechem ensures that its solutions align with current industry trends and regulations.